General performance cookies are applied to be familiar with and examine The true secret effectiveness indexes of the web site which assists in offering an even better user knowledge with the site visitors. Analytics Analytics

Environmental checking shall be done all over set-up And through the entire Media Fill Test, in any way sample web-sites monitored in the course of schedule production runs.

Flooring inside the buffer or cleanse spot are cleaned by mopping the moment everyday when no aseptic operations are in development. Mopping might be executed by trained and supervised custodial staff using accepted agents described in the created processes. Only permitted cleansing and sanitizing brokers are utilized with mindful thing to consider of compatibilities, effectiveness, and inappropriate or toxic residues. Their schedules of use and methods of software are in accord with created methods.

Aseptic Procedure Essential operations are performed by properly trained and certified staff in a very DCCA working with suitable aseptic strategies described in the composed course of action (see Prompt Typical Functioning Procedures). Aseptic procedure is Similarly relevant to your preparing of sterile sensitizing and chemotoxic agents. Having said that, it is critical to acknowledge that supplemental precautions should be used to safeguard the staff and the compounding setting from the potential adverse results of these chemotoxic merchandise.

The media fill evaluates the aseptic assembly and operation of crucial sterile tools, qualifies and evaluates the operators' approach, and demonstrates the environmental controls are adequate to meet The fundamental necessities for making a sterile drug as a result of aseptic processing.

Elements Compounding staff ascertain that elements for CSPs are of the proper identity and proper high-quality utilizing the next information: distributors' labels, labeling, certificates of research, direct chemical Assessment, and expertise in compounding facility storage situations.

Bulk, or unformulated, drug substances and additional substances, or excipients, has to be saved in tightly shut containers beneath temperature, humidity, and lights disorders that happen to be either indicated in official monographs or accepted by suppliers; also the date of receipt within the compounding facility need to be Obviously and indelibly marked on Every single offer of ingredient.

PROCESSING A penned description of specific training and functionality evaluation system for people linked to the usage of aseptic tactics to the planning of sterile items need to be made for every website. This plan equips the staff with the right expertise and trains them while in the necessary competencies essential to accomplish the assigned tasks.

The sealed containers after filling With all the medium are incubated to detect microbial growth for contamination at the best possible temperature.

After the preparing of every admixture, the contents from the container are thoroughly combined and then inspected with the presence of particulate matter, evidence of incompatibility, or other defects.

Think about growing the frequency of media-fill testing at your pharmacy. We strongly advocate that media-fill testing replicates media fill validation the elements website of essentially the most complicated CSP created; which the testing is carried out at the end of the compounding working day or shift; Which three media-fill units are produced by Just about every compounding staff members member at first after which you can at on no less than a quarterly foundation.

The media have to be handed the test for GPT to promote the growth of gram-detrimental and gram-positive bacteria and yeast and molds.

Examine the status board affixed to the tank “Completely ready FOR USE”, also verify the data and be sure that the bottom outlet valve with the mixing tank is shut.

This is often Plainly explained while in the ISO 13408-128 and in PIC/S:26 “Exceeding the action Restrict means that a radical investigation in the failure should be carried out and an entire requalification must be initiated. All produced batches Considering that the failure need to be quarantined until eventually the lead to for failure in the media fill is identified.” PIC/S26 endorses that each one created batches For the reason that final successful system simulation must be taken into account. Desk below illustrates the limits of to start with qualification and requalification in media fill.

Danny Tamberelli Then & Now!

Danny Tamberelli Then & Now! Michelle Pfeiffer Then & Now!

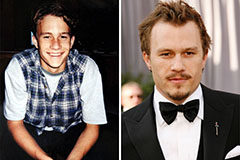

Michelle Pfeiffer Then & Now! Heath Ledger Then & Now!

Heath Ledger Then & Now! Stephen Hawking Then & Now!

Stephen Hawking Then & Now! Kerri Strug Then & Now!

Kerri Strug Then & Now!